wire edm machine is an electro process

The wire tension in the machine configuration is incorrectThe system defaults to set the edge-finding tension to 12. Wire EDM is a type of CNC machining technology capable of unique results.

Applied Sciences Free Full Text Principles And Characteristics Of Different Edm Processes In Machining Tool And Die Steels Html

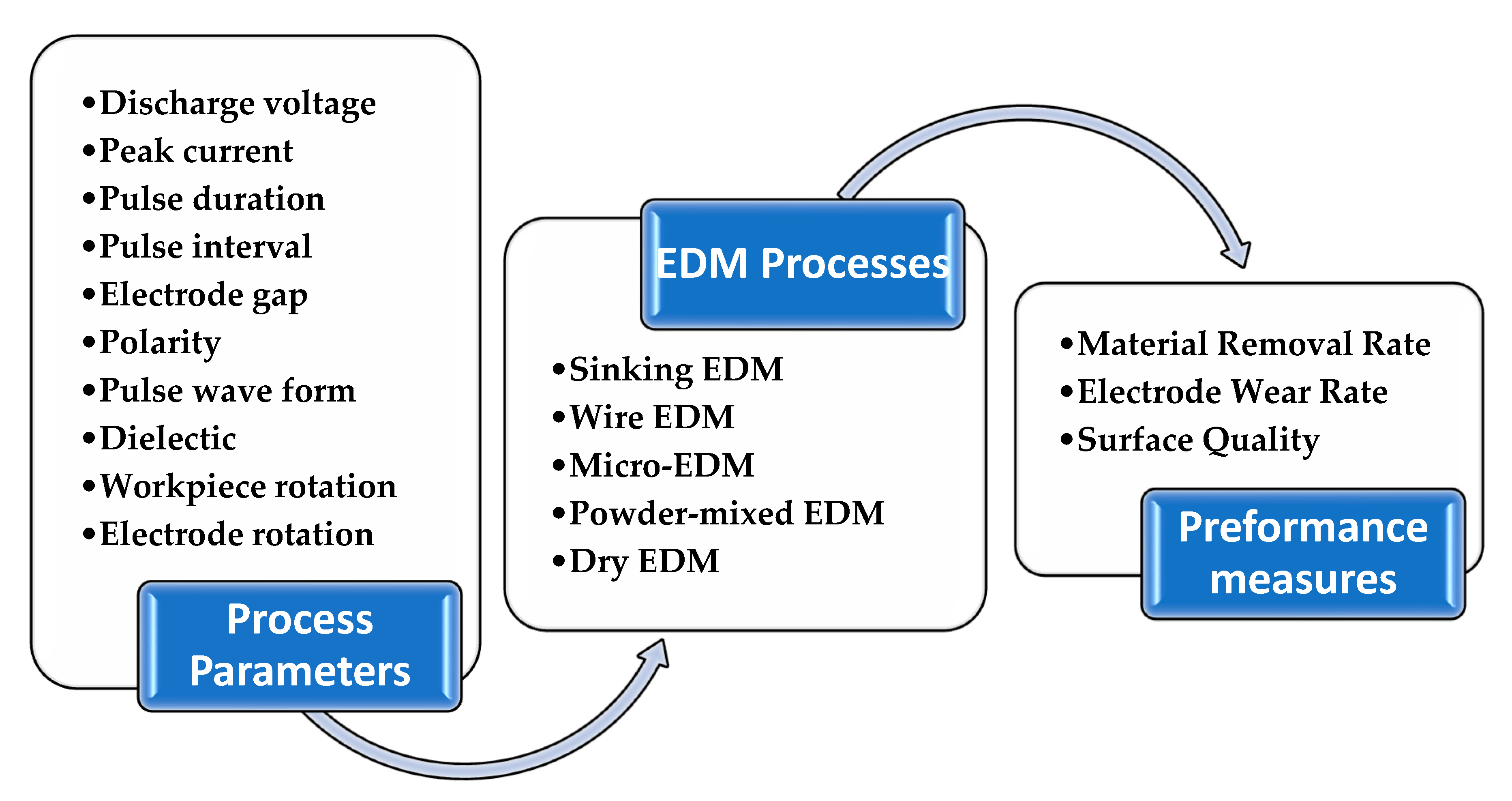

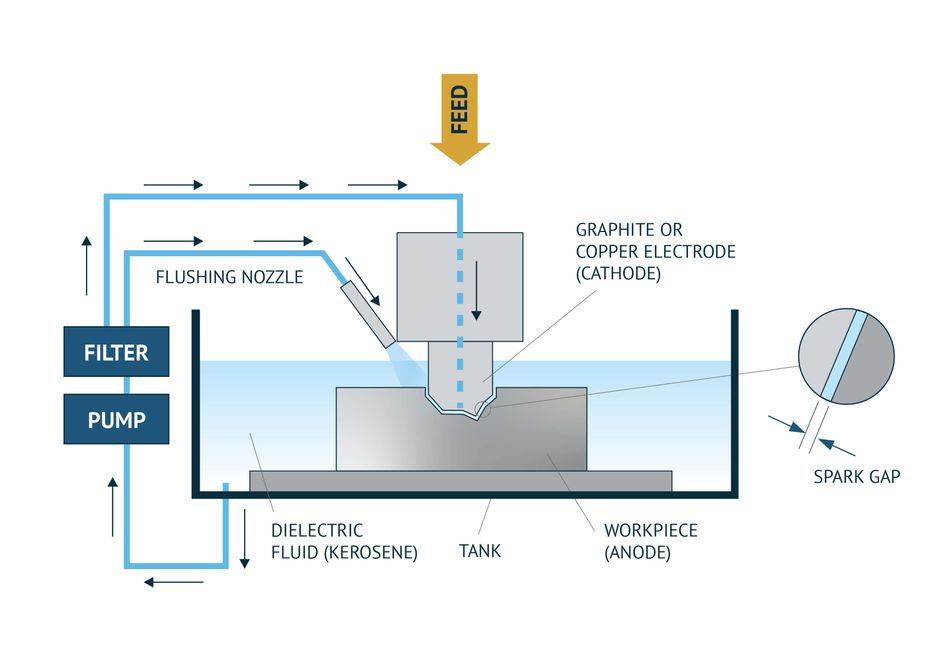

EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry to burn the geometry of the electrode on a metal.

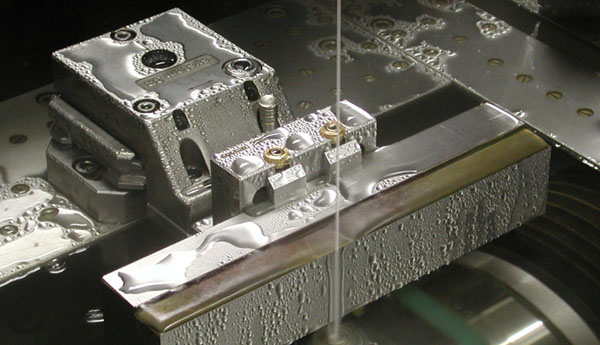

. Wire EDM Machining also known as Spark EDM is an electro thermal production process in which a thin single-strand metal wire usually brass in conjunction with de-ionized water used. This electrically discharged machining process contains a single-stranded metal wire quoted on the workpiece. Electrical discharge machining or EDM is a relatively new process that uses the power of an electro thermal spark to remove the surface material of a conductive workpiece.

EDM is a nonconventional machining process that removes electrical conductive materials according to the thermal energy melting and partial vaporization of the workpiece produced. The nature of the Wire EDM process means that you can achieve shapes and structures that are. Overview of EDM Cutting.

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Wire EDM or Wire Electrical Discharge Machining allows a skilled technician to machine precise complex parts out of hard conductive materials. What wire EDM is was discussed in the article.

However the die is replaced. Wire EDM machines create an electrical. This type of idiom is commonly known as wire-cut or wire cutting EDM.

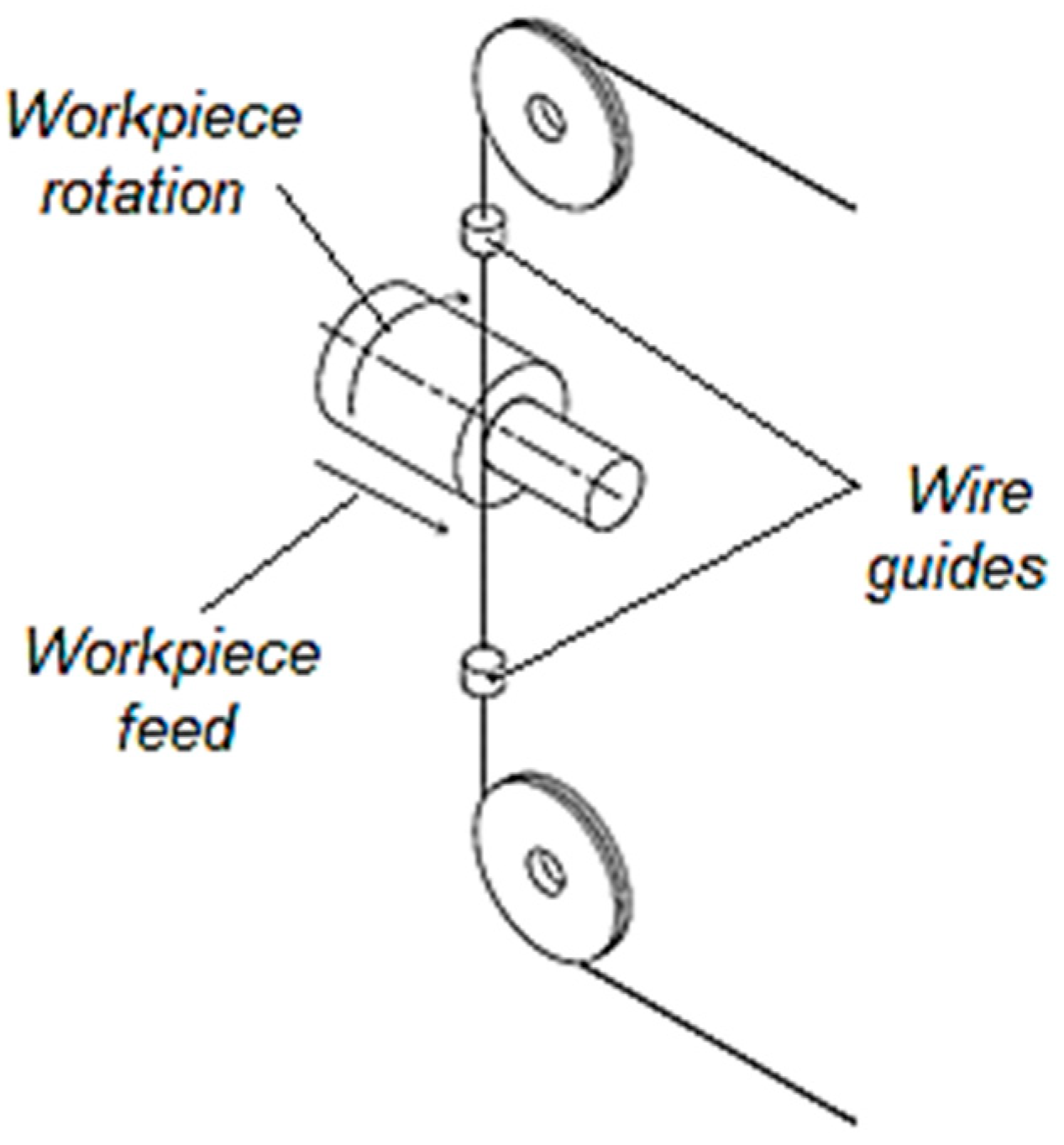

A thin single-strand metal wire and de-ionized water used to conduct electricity are used in the electro thermal production. Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct. If you change to 015mm or 01mm electrode wire you.

Wire EDM otherwise known as wire erosion is commonly used to produce extrusion dies. The servo motor controls the wire electrode ensuring it does not come in contact with the. A non-conventional process though.

It cuts using the same mechanism as die-sinking. The electrodes in the machine are the wire cathode and the workpiece anode. Also known as spark machining cutting EDM cutting is a cutting process that involves the use of electrical discharge to slice through metal workpieces.

Wire EDM machining is an electro thermal. Wire EDM is an electro-thermal production process that uses a thin metal wire alongside deionized water to cut through tough metals.

Electric Discharge Machining Edm Wire Hitachi Metals Ltd

Edm Past Present And Future Asia Pacific Metalworking Equipment News Manufacturing Automation Quality Control

Study Of Process Parameter Of Wire Electric Discharge Machining The Review Semantic Scholar

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Electrical Discharge Machining Construction Application Pros And Cons

What Is Wire Edm Electrical Discharge Machining Xact

Energy Efficient Edm Why Generator Technology Makes All The Difference

Electrical Discharge Machining Edm Everything You Need To Know

Wire Edm Cutting Vs Laser Cutters

Wire Electric Discharge Machining Wire Edm Youtube

What Is Electrical Discharge Machining Edm Get It Made

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Edm Machining Components Types Applications And Advantages

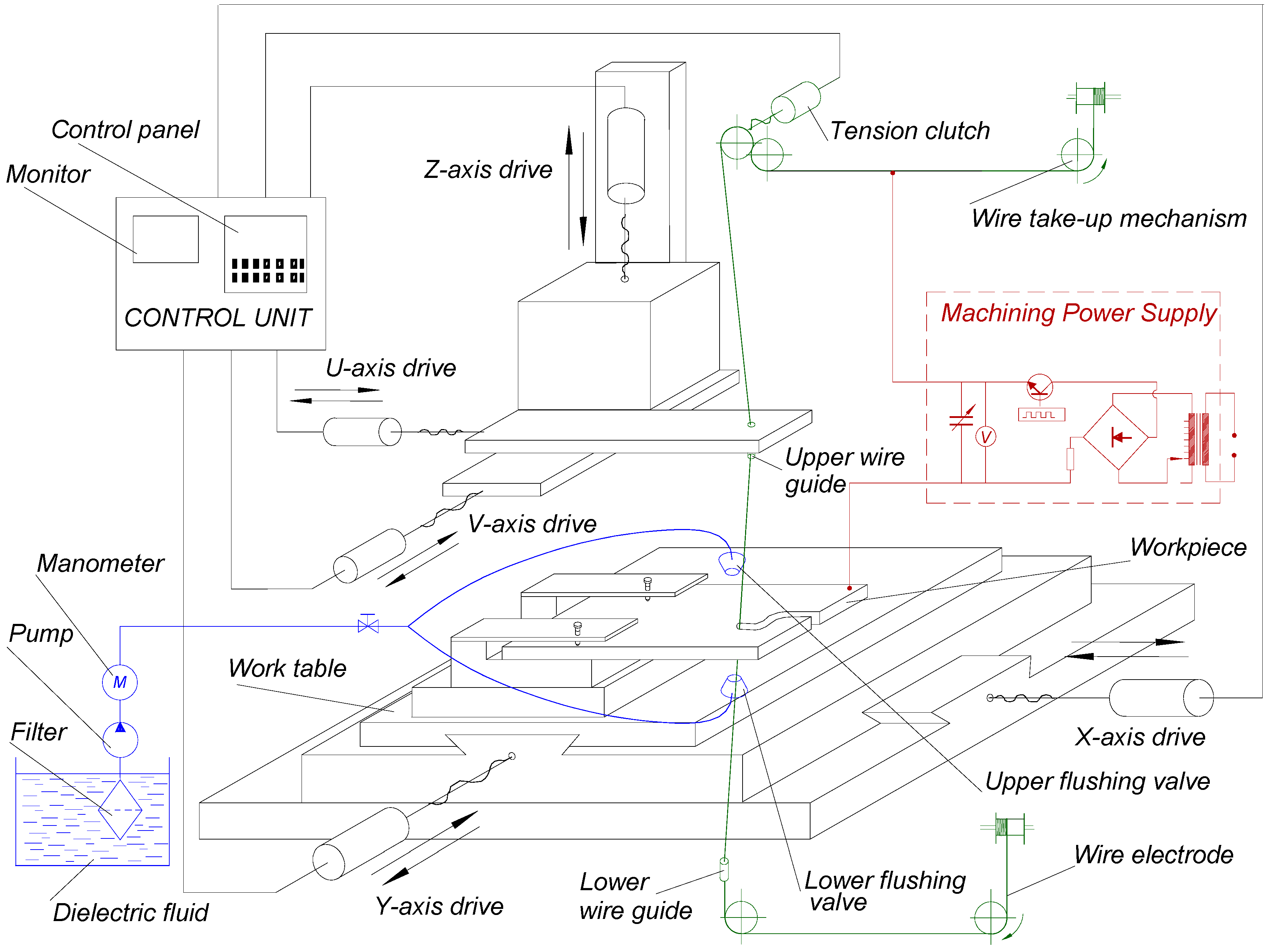

Line Diagram Of Wire Cut Edm Process Download Scientific Diagram

Advantages Of Wire Edm Machining Sans

Buying A Wire Edm Part 4 Dielectric Fluid Maintenance Modern Machine Shop

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

What Is Electrical Discharge Machining Edm Get It Made

Mechanical Engineering Electrical Discharge Machining Edm Principles